Solar panels also use metal frames consisting of racking components, brackets, reflector shapes, and troughs to better support the panel structure. This enables the use of cells with a high cost per unit area (such as gallium arsenide) in a cost-effective way. Some special solar PV modules include concentrators in which light is focused by lenses or mirrors onto smaller cells.

Bypass diodes may be incorporated or used externally, in case of partial module shading, to maximize the output of module sections still illuminated. The conducting wires that take the current off the modules are sized according to the current rating and may contain silver, copper or other non-magnetic conductive transition metals.

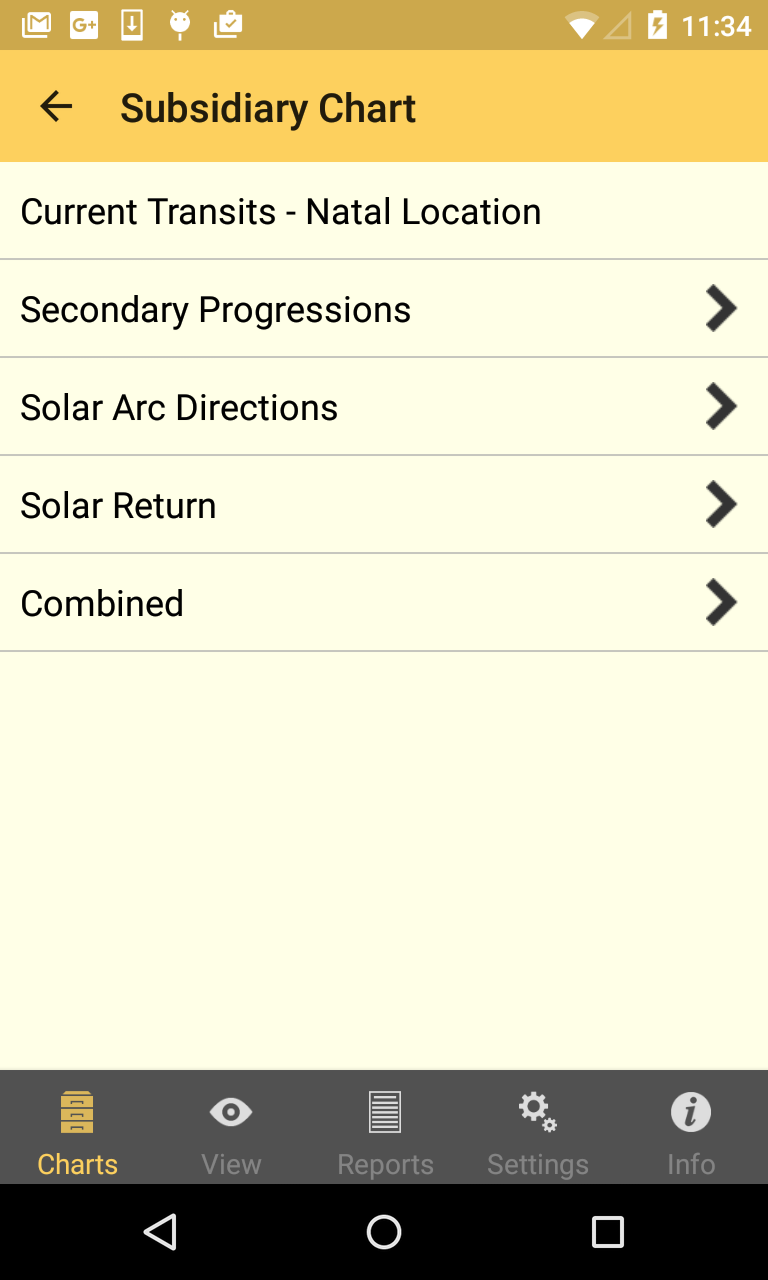

Solar fire gold 9 crack series#

Module electrical connections are made in series to achieve a desired output voltage or in parallel to provide a desired current capability (amperes) of the solar panel or the PV system. External connections for most photovoltaic modules use MC4 connectors to facilitate easy weatherproof connections to the rest of the some system. Ī PV junction box is attached to the back of the solar panel and functions as its output interface. The manufacture specifications on solar panels are obtained under standard condition which is not the real operating condition the solar panels are exposed to on the installation site. The power (in watts) of the module is the mathematical product of the voltage (in volts) and the current (in amperes) of the module. The cells are usually connected electrically in series, one to another to the desired voltage, and then in parallel to increase current. Most modules are rigid, but semi-flexible ones based on thin-film cells are also available. Cells must be protected from mechanical damage and moisture. The structural ( load carrying) member of a module can be either the top layer or the back layer. Most modules use wafer-based crystalline silicon cells or thin-film cells. Photovoltaic modules use light energy ( photons) from the Sun to generate electricity through the photovoltaic effect. The surface passivation process has since been critical to solar cell efficiency.

Atalla developed the process of silicon surface passivation by thermal oxidation at Bell Labs. In 1954, this design was first used by Bell Labs to create the first commercially viable silicon solar cell. In 1939, Russell Ohl created the solar cell design that is used in many modern solar panels. In 1881, Charles Fritts created the first commercial solar panel, which was reported by Fritts as "continuous, constant and of considerable force not only by exposure to sunlight but also to dim, diffused daylight." However, these solar panels were very inefficient, especially compared to coal-fired power plants. After this discovery, William Grylls Adams and Richard Evans Day published "The action of light on selenium" in 1876, describing the experiment they used to replicate Smith's results.

The observation by Becquerel was not replicated again until 1873, when Willoughby Smith discovered that the charge could be caused by light hitting selenium. Though these initial solar panels were too inefficient for even simple electric devices they were used as an instrument to measure light. In 1839, the ability of some materials to create an electrical charge from light exposure was first observed by Alexandre-Edmond Becquerel. See also: Solar cell § History, and Timeline of solar cells

0 kommentar(er)

0 kommentar(er)